Why choose us

Where Precision Engineering Meets Impeccable Design

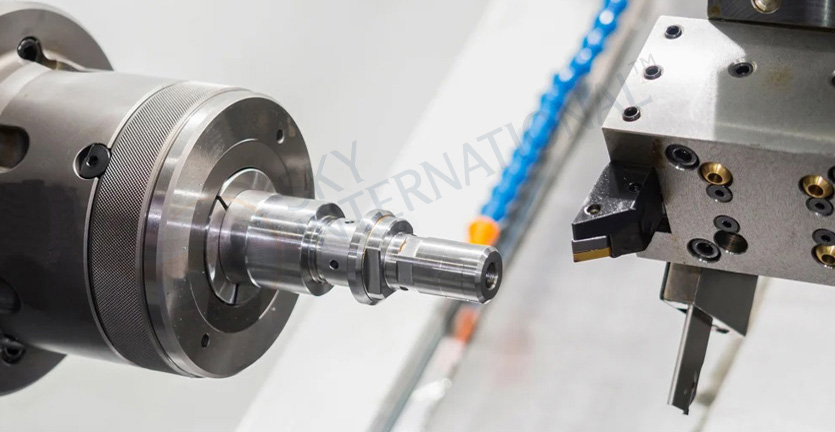

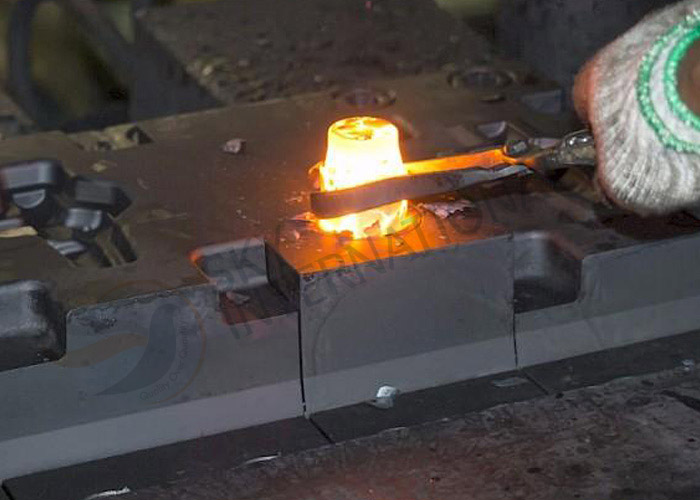

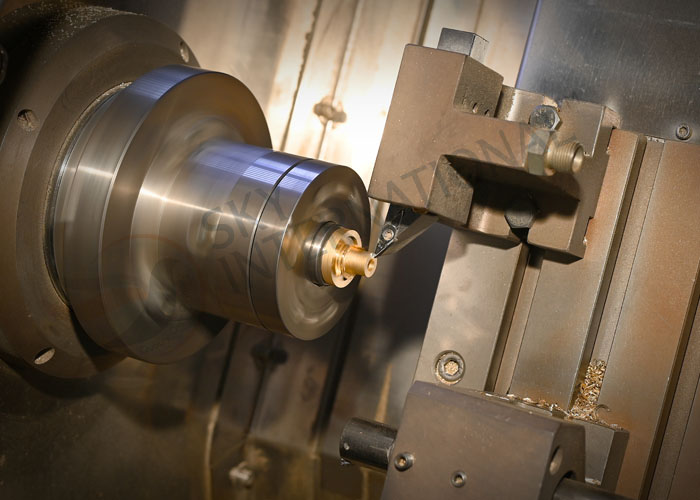

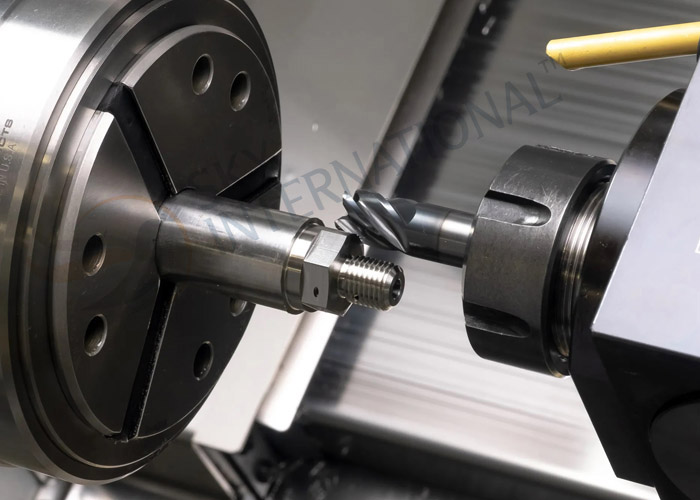

We have established a state of art infrastructure with latest automated machineries which is segmented into different divisions for smooth and hassle free working. With over 55,000 sq. ft. manufacturing area, segmented for each area of operation, each segment has necessary facilities including modern machineries and tools. Our infrastructure has not only enabled smooth production of large batch but also helped us to make our position strong in global market.

-

Skilled employee dedicated to development.

-

Modern machines for better quality products

-

Scheduled quality checks to maintain quality benchmarks.

Here’s a list of equipment that helps us achieve

our promise of perfection

Manufacturing Unit

Production Machines

Type of Machine |

Machining Range |

||

| CNC Linear | 5.00 mm to 50.00 mm (Length : 120.00 mm) | ||

| CNC Turret | 5.00 mm to 110.00 mm (Length : 250.00 mm) 5.00 mm to 150.00 mm (Length : 250.00 mm) |

||

| VMC | 200.00 mm X 200.00 X 300.00 mm | ||

| Cam OperatedAutomatic Machine | 1.00 mm to 8.00 mm | ||

| Cam Operated Single Spindle Machine | 20.00 mm to 32.00 mm Round 15.00 mm to 25.00 mm Round 11.50 mm to 19.00 mm Round |

||

| Milling Machine | 2.00 to 20.00 mm 5.00 to 40.00 mm |

||

| Cutting Machine | 1.00 mm to 40 mm Round 20 mm to 200 mm Round |

||

| Press | 2.00 to 15.00 mm Depth :

20.00 mm 15.00 mm To 50.00 mm Depth : 30.00 mm 0.100 to 1.000 kgs Forging Marking Depth 0.10 To 0.70 mm |

||

| Hot Air Oven | 450 °C Max | ||

| Shot Blasting | 70.00 mm X 70.00 X 300.00 mm (Length : 400.00 mm) | ||

Get Instant Quote

Your email address will not be published.

Required fields are marked *